The core difference between MOPA lasers and ordinary Q-switched fiber laser marking machines lies in the tunability of pulse parameters, working principle, and application scenarios: MOPA achieves independent tunability of pulse width and frequency (2ns–500ns) through electrical modulation, suitable for fine processing; while Q-switching technology uses acousto-optic modulation to fix the pulse width (80ns–140ns), suitable for rough processing such as deep metal engraving.

Differences in Working Principles:

MOPA Laser: Employs Master Oscillator Power Amplifier technology, where an electrical signal drives a semiconductor laser chip to generate seed light, which is then amplified by fiber optics, achieving flexible control of pulse parameters.

Q-switched Fiber Laser: Generates pulses by periodically adjusting the resonant cavity loss through an acousto-optic modulator (AOM), with a simple structure but fixed parameters.

Technical Parameter Comparison:

1. Pulse Width:

· MOPA: Arbitrarily tunable from 2ns–500ns, small heat-affected zone.

· Q-switched: Fixed 80ns–140ns, cannot be adjusted.

2. Repetition Rate:

· MOPA: Up to MHz level (e.g., 4000kHz), high efficiency.

· Q-switching: Upper limit approximately 100kHz, narrow adjustment range.

3. Peak Power:

· Both can reach the kilowatt level, but MOPA maintains a stable high peak power through parameter combinations.

Application Scenarios Differences

1. MOPA Applicable Scenarios:

· Fine processing: Blackening of alumina, color marking on stainless steel (e.g., mobile phone casings).

· Sensitive materials: Electronic components, medical devices (minimal thermal damage).

2. Q-switching Applicable Scenarios:

· Rough processing: Deep engraving of metals (e.g., stainless steel cutting), marking on high-reflectivity materials (gold/copper).

Technical Data

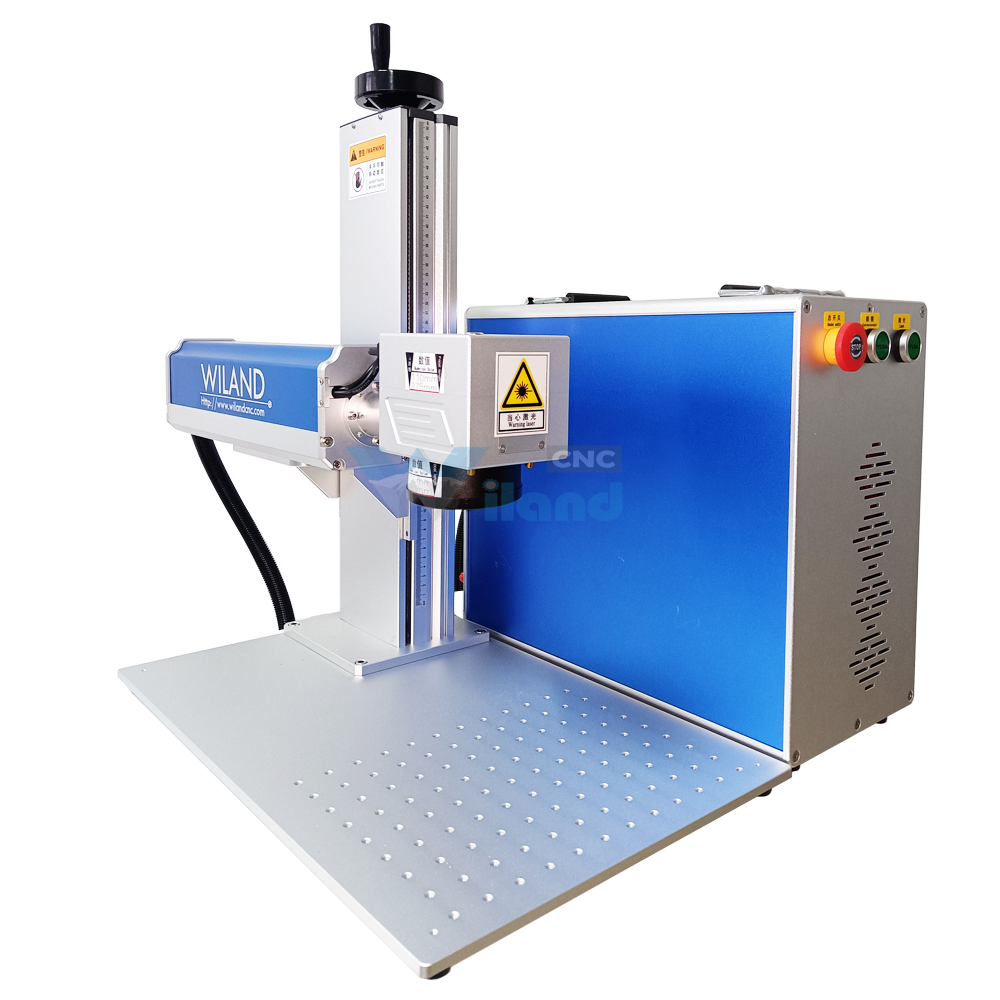

WLD-MOPA-100W Components & Technical Specification | ||||

Working Area | 7.9”x7.9”(200*200mm)/11.8”x11.8”(300*300mm) | Laser Power | 100W | |

Laser Source | MOPA JPT M7 Laser | Laser Wavelength | 1064nm | |

Galvanometer | High-Speed Sino-Galvo | Laser Repetition Frequency | 1-4000kHz | |

Control Card | Original BJJCZ Control Board | Pulse Duration | 2-500ns | |

Software | EZCAD2/EZCAD2 Lite | Colored Marking | Support 1-3 colors | |

Power Supplies | 5V,15V,24V | Marking Line Speed | ≤10000mm/s | |

Z-Axis Control | Manual | Engraving Depth | ≤1mm(It depends on the material) | |

F-Theta Field Lens | Working area 300x300mm Focal Length 482mm | Positioning Accuracy | ±0.1 μm | |

Optional Lens | 70*70/110*110/200*200/300*300 | Power Consumption | ≤1000W | |

Power Requirements | AC220V/50Hz Or AC110V/60Hz(According to local electricity supply) | Fiber Power | Adjustable from 10-100% | |

Correction Software | CorFile2 | Operation System | Win7/Win8/Win10/Win11 | |

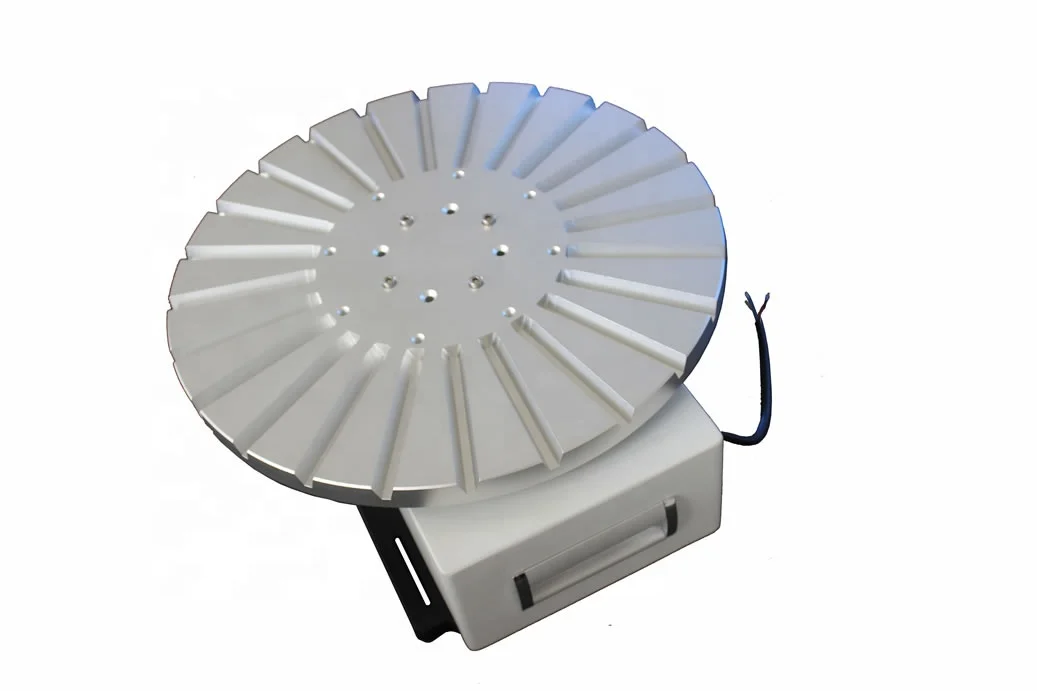

Rotary | D80 Rotary Attachment Set | Marking Format | AI、DXF、PLT、JPG、BMP、Bar Code 、QR Code、 etc | |

Warranty | 2 Year | Temperature/Humidity | 0-35°C;10-95%,Non-Condensing | |