Working Accuracy:±0.002MM

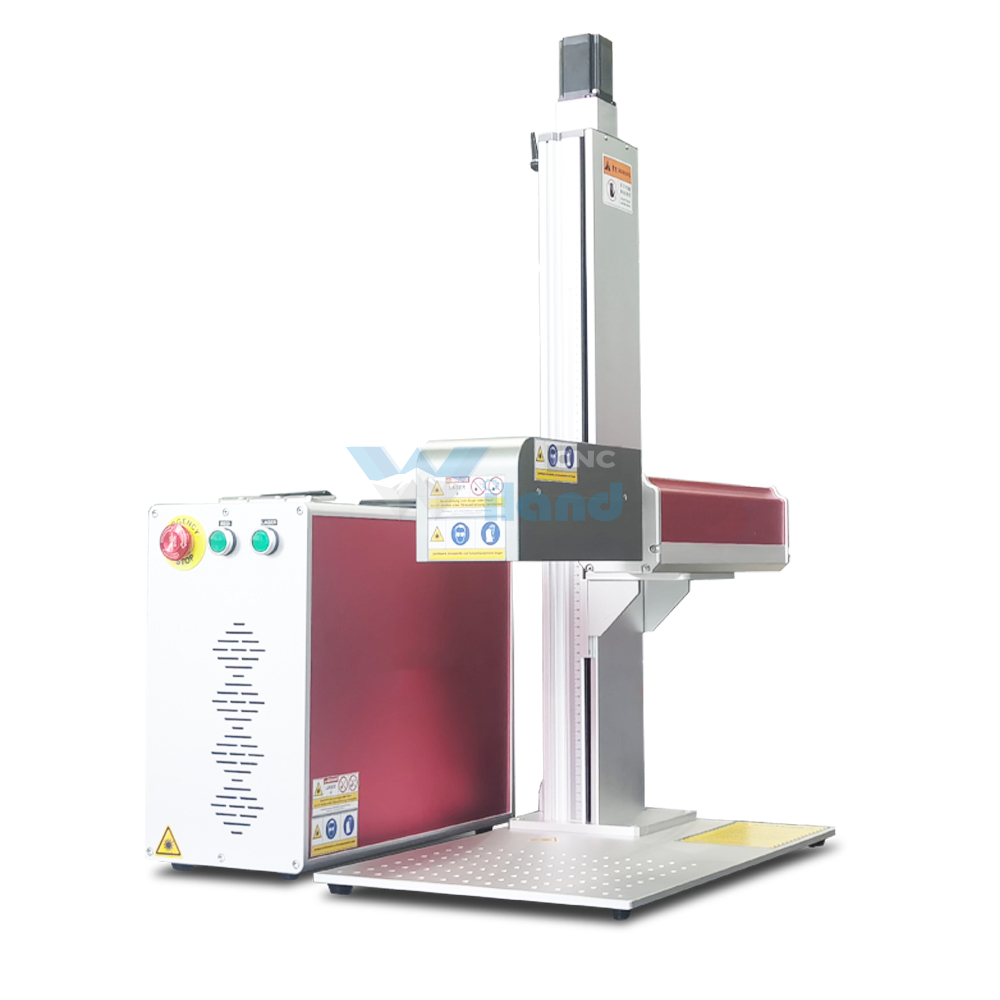

3D laser marking machine is an advanced laser marking equipment that can perform precise marking operations on three-dimensional surfaces. Compared with traditional flat laser marking machines, 3D laser marking machines have higher flexibility and can handle workpieces of various complex shapes and curved surfaces, such as metals, plastics, ceramics and other materials. The equipment uses high-speed and high-precision laser scanning technology to make the marking content clear, durable and have high visual effects. It is widely used in electronics, automobiles, aerospace, medical equipment and other industries to meet the diverse needs of identification, serial numbers, QR codes, etc. The emergence of 3D laser marking machines has greatly improved the personalization and traceability of products, and provided strong technical support for modern manufacturing.

The core difference between 3D marking machines and ordinary (traditional 2D) marking machines lies in their adaptability to the processed surface and their optical path control methods. This directly leads to significant differences in their application range, accuracy, and efficiency.

Core Differences: Processing Capability and Surface Adaptability

Ordinary 2D Marking Machines: Use a back-focusing method, with the laser focus fixed on a single plane. It can only mark on flat surfaces, requiring extremely high surface flatness. If the workpiece surface has curved, arc-shaped, spherical, or uneven surfaces, the 2D marking machine cannot effectively focus, resulting in blurry marks, inconsistent depth, or even failure to complete the marking.

3D Marking Machines: Use a front-focusing (or dynamic focusing) optical mode, equipped with a three-dimensional dynamic scanning galvanometer and a dynamic focusing mount. It can control the focal length of the laser beam in real time through software, automatically compensating for height differences on the workpiece surface. Therefore, it can perform one-time, high-precision marking on irregular, uneven surfaces such as curved surfaces, arc surfaces, spherical surfaces, deep engravings, and reliefs, greatly expanding the application range of laser marking.

Optical Path Control and Precision

Ordinary 2D Marking Machine: The optical path is relatively simple, focusing through a fixed field lens. Changing the scanning range (area) usually requires replacing the physical lens.

3D Marking Machine: By jointly controlling the galvanometers along the X, Y, and Z axes, the spot size and focal point position can be adjusted in real time during scanning. This ensures that the laser energy density remains consistent throughout the processing area, resulting in uniform and clear marking effects. Furthermore, its software-controlled area switching method is faster and more flexible than changing physical lenses.

Application Effect and Efficiency

Ordinary 2D Marking Machine: Suitable for simple and regular marking such as planar markings, barcodes, and serial numbers.

3D marking machines not only perform traditional marking but also deep engraving, relief marking, and multi-color marking (achieving black and white marking effects on the same plane), resulting in richer and more diverse marking effects to meet personalized and high-value-added processing needs. For complex curved workpieces, 3D marking machines can complete the processing in one pass, significantly improving efficiency and avoiding the need for multiple clamping operations or special tooling that may be required in traditional methods.

In summary, 3D marking machines are an advanced technology developed to overcome the limitations of 2D marking machines in curved surface processing. They possess unparalleled advantages in adapting to complex curved surfaces, achieving high-precision dynamic focusing, improving processing efficiency, and enriching marking effects.

1. Good beam quality and smaller focal spot for ultra-fine marking.

2. Subvert the traditional two-dimensional marking mode, to achieve all-round marking, can be engraved bevel, cylinder, cone, sphere and other different 3D shapes.

3. Automatically calculates radian and automatically adjusts focus for marking multi-level large format, 3D curved surfaces and more.

4. Adopt multi-axis dynamic zoom technology to track deep curve focus in real time.

5. Dynamic axes coordinately adjust the focus and adjust the light spot in real time to ensure the uniformity and consistency of the light spot and achieve higher accuracy.

6. 3D dynamic focusing system, can realize deep carving, relief carving, curved surface accurate laser carving, light spot delicate, uniform and consistent, the effect is more beautiful, more efficient.

7. Wiland Fiber Laser Marking Machine is subjected to strict ageing tests and continuous 24-hour laser beam output before leaving our factory to ensure 100% machine stability.

Product Advantages:

1. High precision and fineness: 3D laser marking machines are able to mark complex three-dimensional surfaces with high precision, ensuring clear and readable markings that meet strict quality standards.

2. Adapt to a variety of materials: The equipment can mark on a variety of materials such as metals, plastics, ceramics, glass, etc., with a wide range of applications to meet the marking needs of different materials.

3. Flexible response to complex shapes: 3D laser marking machines are able to handle a variety of non-planar, curved and irregularly shaped workpieces, and are suitable for products of various shapes, such as automotive parts, medical devices, etc.

4. Permanent marking: Laser marking technology treats materials through photochemical treatment, and there will be no shedding or fading, ensuring the permanence and durability of the marking.

5. Extremely high speed: The 3D laser marking machine has a fast marking speed, which greatly improves production efficiency and is suitable for mass production occasions.

6. Environmentally friendly and pollution-free: The laser marking process does not require chemical materials or inks, is relatively environmentally friendly, and generates less waste and noise, which helps to improve the working environment.

7. Easy to customize: Its flexibility allows the marking content to be quickly changed as needed, which is suitable for personalized and small-batch customized production.

8. Reduce labor costs: The laser marking machine has a high degree of automation, which reduces the dependence on manual operation, reduces labor costs and errors.

9. Low maintenance cost: Laser marking machines usually have a long service life and low maintenance requirements, which further reduces operating costs. 3D laser marking machines have become an indispensable tool in modern manufacturing due to their precision, flexibility and efficiency.

WLD-3D-60W Components & Technical Specification | ||||

Working Area | 7.9”x7.9”(200*200mm)/11.8”x11.8”(300*300mm) | Laser Power | 60W | |

Laser Source | MOPA JPT M7 Laser | Laser Wavelength | 1064nm | |

Galvanometer | High-Speed 3D Sino-Galvo | Laser Repetition Frequency | 1-4000kHz | |

Control Card | Original BJJCZ Control Board | Pulse Duration | 2-500ns | |

Software | EZCAD3 | Colored Marking | Support 1-3 colors | |

Power Supplies | 5V,15V,24V | Marking Line Speed | ≤10000mm/s | |

Z-Axis Control | Electrical | Engraving Depth | ≤1mm(It depends on the material) | |

F-Theta Field Lens | Working area 300x300mm Focal Length 482mm | Positioning Accuracy | ±0.1 μm | |

Optional Lens | 70*70/110*110/200*200/300*300 | Power Consumption | ≤1000W | |

Power Requirements | AC220V/50Hz Or AC110V/60Hz(According to local electricity supply) | Fiber Power | Adjustable from 10-100% | |

Correction Software | CorFile2 | Operation System | Win7/Win8/Win10/Win11 | |

Rotary | D80 Rotary Attachment Set | Marking Format | AI、DXF、PLT、JPG、BMP、Bar Code 、QR Code、 etc | |

Warranty | 2 Year | Temperature/Humidity | 0-35°C;10-95%,Non-Condensing | |

WLD-3D-100W Components & Technical Specification | ||||

Working Area | 7.9”x7.9”(200*200mm)/11.8”x11.8”(300*300mm) | Laser Power | 100W | |

Laser Source | MOPA JPT M7 Laser | Laser Wavelength | 1064nm | |

Galvanometer | High-Speed 3D Sino-Galvo | Laser Repetition Frequency | 1-4000kHz | |

Control Card | Original BJJCZ Control Board | Pulse Duration | 2-500ns | |

Software | EZCAD3 | Colored Marking | Support 1-3 colors | |

Power Supplies | 5V,15V,24V | Marking Line Speed | ≤10000mm/s | |

Z-Axis Control | Electrical | Engraving Depth | ≤1mm(It depends on the material) | |

F-Theta Field Lens | Working area 300x300mm Focal Length 482mm | Positioning Accuracy | ±0.1 μm | |

Optional Lens | 70*70/110*110/200*200/300*300 | Power Consumption | ≤1000W | |

Power Requirements | AC220V/50Hz Or AC110V/60Hz(According to local electricity supply) | Fiber Power | Adjustable from 10-100% | |

Correction Software | CorFile2 | Operation System | Win7/Win8/Win10/Win11 | |

Rotary | D80 Rotary Attachment Set | Marking Format | AI、DXF、PLT、JPG、BMP、Bar Code 、QR Code、 etc | |

Warranty | 2 Year | Temperature/Humidity | 0-35°C;10-95%,Non-Condensing | |