Multi-angle recognition:360°

Engraving speed:≤7000mm/s

laser wavelength: 355nm

laser power:3W/5W/10W/12W/15W

camera:200/500/1000/1200/2000 megapixels (optional)

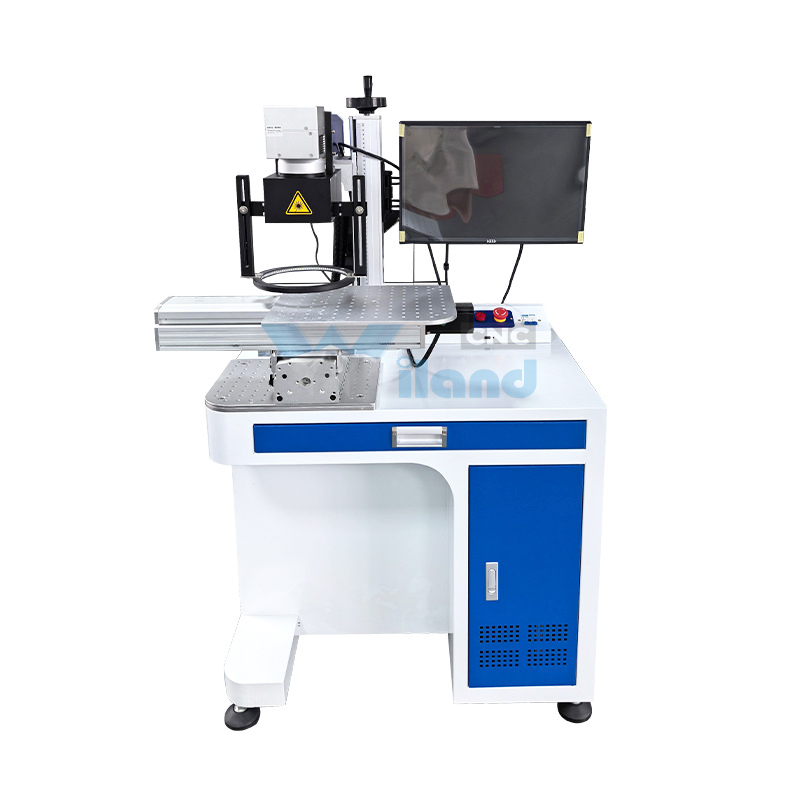

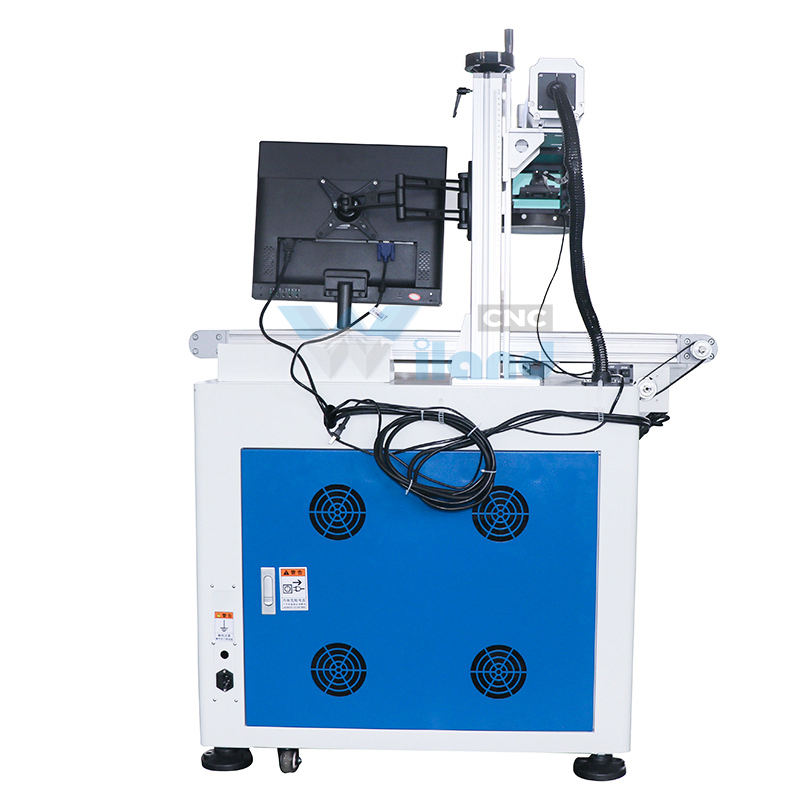

Machine Introduction

The Wiland vision-positioning laser marking machine uses a CCD camera positioning system to guide the laser for marking, ensuring accurate positioning. Marked products can be placed anywhere. Multiple products can be placed at once. The software can automatically recognize any shape and automatically mark multiple products simultaneously.

The processed products can be round, square, or irregular in shape, all of which can be identified. This process is particularly suitable for small products, eliminating the need for positioning trays and fixing fixtures, and significantly reducing the processing cycle of laser marking.

Visual positioning laser marking machines are suitable for high-speed positioning marking in industries such as electronic product production lines, electroacoustic devices, chargers, transformers, relays, connectors and other plastic products, auto parts, medical accessories, clothing zippers, small hardware parts, PCB/FPC circuit boards, and molds.

Features of CCD Vision Positioning Laser Marking Machine

1. Precisely guides laser marking position. Within the machine vision's field of view, it provides omnidirectional (unordered product placement, arbitrary angle placement) and arbitrary number marking. Product marking is automatically recognized by the camera, eliminating the tedious process of manual galvanometer calibration.

2. The camera has a large imaging field of view, suitable for marking any flat product. You can choose static or fly-guided laser marking to meet different customer needs.

3. It can be integrated with various wavelength laser paths, such as fiber lasers, CO2 lasers, and ultraviolet lasers. It can be controlled via guide rails to achieve splicing marking of large-format products, suitable for most products.

4. Marking characters can be recognized (OCR). Compared with barcode and QR code recognition, it can be connected to the MES system via Ethernet or serial communication.

5. The software is independently developed and supports non-standard customization. XYZ axes can be added according to the actual product characteristics and various assembly lines can be inserted. It can also be connected to a vibrating plate and automatic feeder to achieve fully automatic vision positioning marking.

6. Simple user interface + one-click correction function, making operation easier and clearer, and easy for ordinary employees to use.

| Product Type | CCD Visual laser marking machine | Multi-angle recognition | 360° |

| Engraving speed | ≤7000mm/s | Power consumption | 1300W |

| laser wavelength | 355nm | Power supply | 220V/50Hz |

| laser power | 3W/5W/10W/12W/15W | Counting function | Total number of statistics, number of batches of statistics |

| camera | 200/500/1000/1200/2000 megapixels (optional) | ||

| Feeding method | Manual feeding, vibratory feeder feeding, robotic arm feeding (optional) | ||

| Transmission method | Conveyor belt + stepper motor/servo motor (optional) | ||

| light source | Strip light/ring light/area light/backlight (optional) | ||