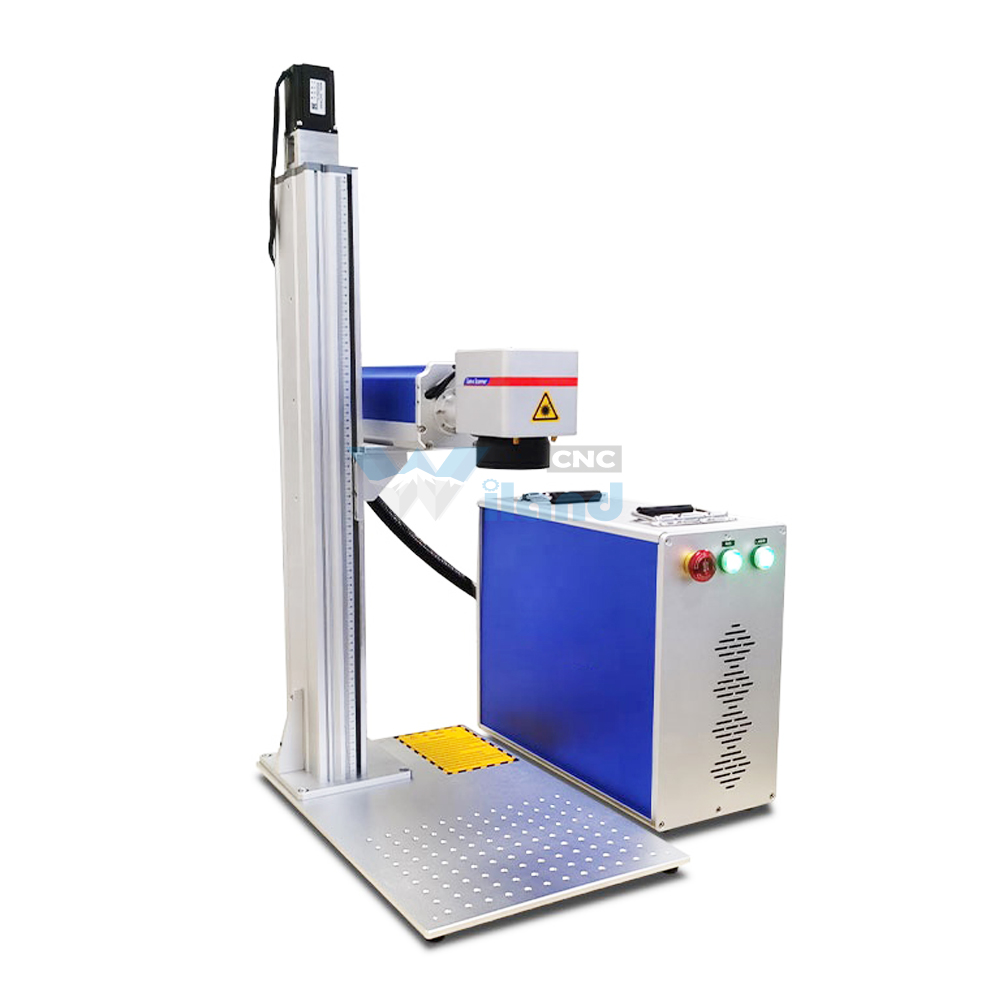

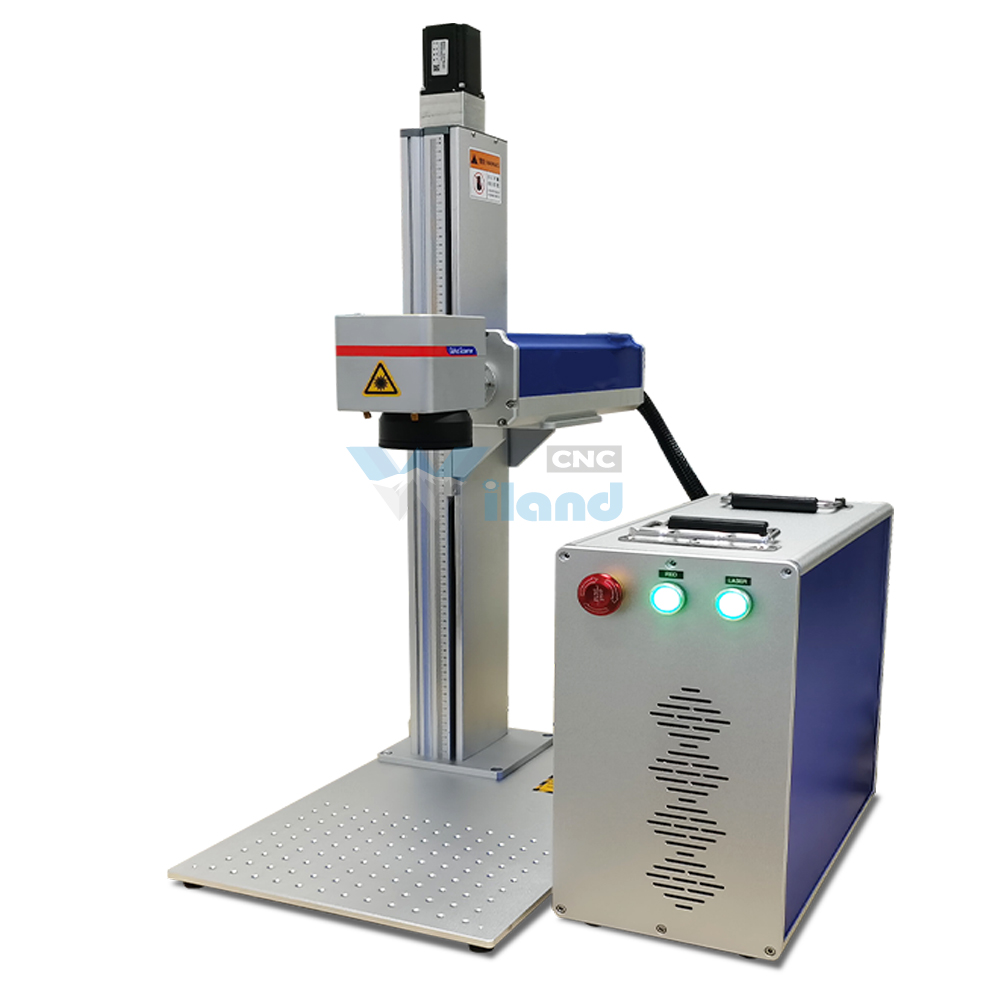

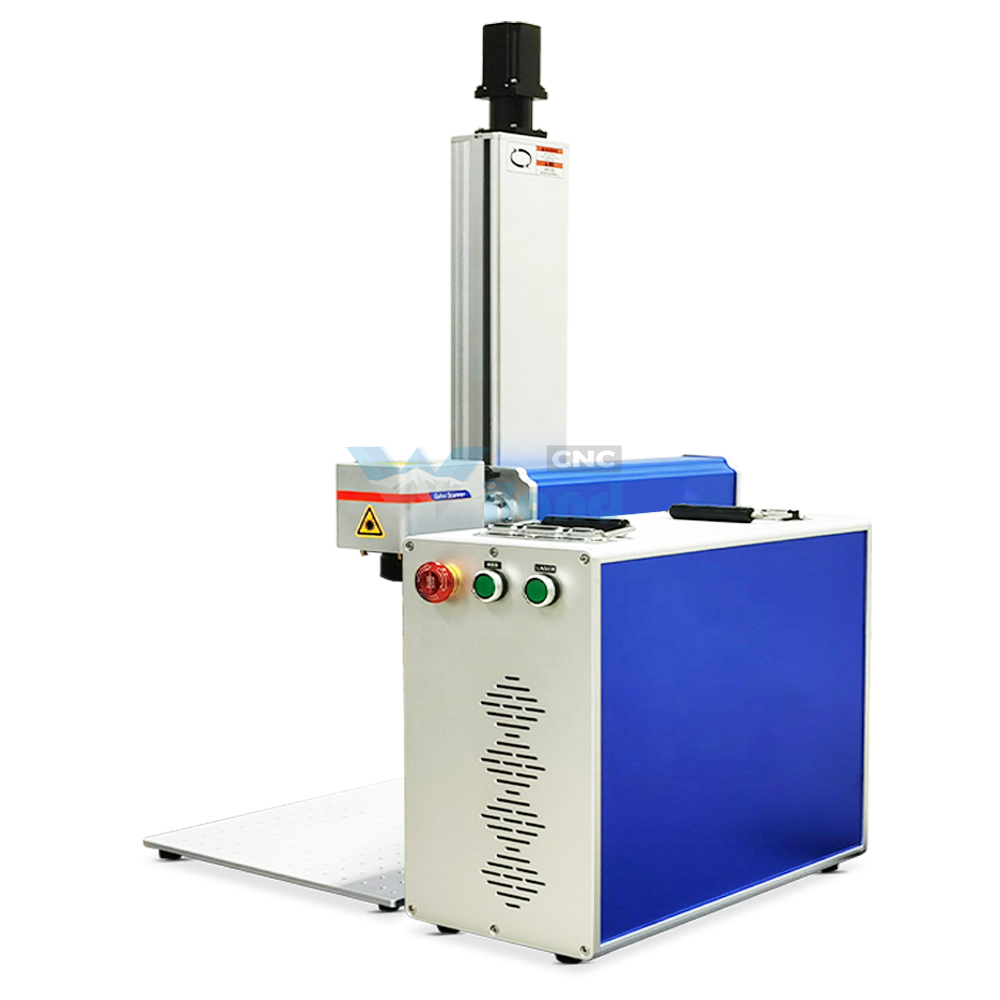

2.5D Fiber Laser Marking Machine is a kind of laser equipment with specific marking range and processing capability, which combines the characteristics of 2D and 3D marking, and can realize both flat and relief marking, not only marking on the flat surface, but also realizing engraving marking on the high and low differences of the object's surface by adjusting the laser's focal length.

1. Small size, easy to carry and save space.

2. The z-axis uses a motorized column that is fine-tuned to the appropriate position as the depth of engraving changes to achieve relief.

3. Adopting imported scanning system and scanning head, automatic focusing, no need to manually adjust, work more convenient.

4. Adopt red light positioning system, easy positioning and high positioning accuracy.

5. High-speed focus scanning system with short pulse, high peak power and high pulse repetition frequency. Working efficiency is 20% higher than similar models.

6. No adjustment, no maintenance, no consumables, long service life of up to 100,000 hours.

Product Advantage :

1. High-precision markingMicron-level positioning: 2.5D laser marking technology can achieve very fine marking, and can depict clear and detailed patterns and text on the surface of the material with an accuracy of up to micron level.

2. Adaptive focal length adjustmentDynamic focus: This technology has the ability to adjust the focal length in real time, and can automatically adapt to the ups and downs and curvature of the workpiece surface to ensure the best marking effect on surfaces of various shapes.

3. High speedFast marking: Compared with traditional printing and etching methods, laser marking is significantly faster, greatly improving production efficiency and suitable for mass production.

4. Complex shape processing abilityCurved and irregular surfaces: This technology can mark on various complex surfaces (such as bevels, concave and convex surfaces, curved surfaces), suitable for various forms of workpieces.

5. High-quality logo durabilityWear and corrosion resistance: Laser marking physically changes the surface of the material instead of adding any coating, making the logo highly wear-resistant and corrosion-resistant, and can remain clear for a long time.

6. Flexible design and personalizationCustomization function: Users can design the content of the logo according to their needs, such as patterns, text, serial numbers, etc., which greatly meets personalized needs.

7. Environmental protectionPollution-free process: The laser marking process does not use any chemical substances and does not produce waste, which meets the requirements of modern environmentally friendly production.

8. SafetyOperational safety: When using laser processing, the operation is safer, and the equipment design usually takes safety protection into consideration to reduce operational risks.

9. Low maintenance costLess maintenance requirements: Laser marking equipment usually has lower daily maintenance requirements, and its durability and stability help reduce long-term use costs.

WLD-2.5D-60W Components & Technical Specification | ||||

Working Area | 7.9”x7.9”(200*200mm)/11.8”x11.8”(300*300mm) | Laser Power | 60W | |

Laser Source | MOPA JPT M7 Laser | Laser Wavelength | 1064nm | |

Galvanometer | High-Speed Sino-Galvo | Laser Repetition Frequency | 1-4000kHz | |

Control Card | Original BJJCZ Control Board | Pulse Duration | 2-500ns | |

Software | EZCAD3 | Colored Marking | Support 1-3 colors | |

Power Supplies | 5V,15V,24V | Marking Line Speed | ≤10000mm/s | |

Z-Axis Control | Electrical | Engraving Depth | ≤1mm(It depends on the material) | |

F-Theta Field Lens | Working area 300x300mm Focal Length 482mm | Positioning Accuracy | ±0.1 μm | |

Optional Lens | 70*70/110*110/200*200/300*300 | Power Consumption | ≤1000W | |

Power Requirements | AC220V/50Hz Or AC110V/60Hz(According to local electricity supply) | Fiber Power | Adjustable from 10-100% | |

Correction Software | CorFile2 | Operation System | Win7/Win8/Win10/Win11 | |

Rotary | D80 Rotary Attachment Set | Marking Format | AI、DXF、PLT、JPG、BMP、Bar Code 、QR Code、 etc | |

Warranty | 2 Year | Temperature/Humidity | 0-35°C;10-95%,Non-Condensing | |

WLD-2.5D-100W Components & Technical Specification | ||||

Working Area | 7.9”x7.9”(200*200mm)/11.8”x11.8”(300*300mm) | Laser Power | 100W | |

Laser Source | MOPA JPT M7 Laser | Laser Wavelength | 1064nm | |

Galvanometer | High-Speed Sino-Galvo | Laser Repetition Frequency | 1-4000kHz | |

Control Card | Original BJJCZ Control Board | Pulse Duration | 2-500ns | |

Software | EZCAD3 | Colored Marking | Support 1-3 colors | |

Power Supplies | 5V,15V,24V | Marking Line Speed | ≤10000mm/s | |

Z-Axis Control | Electrical | Engraving Depth | ≤1mm(It depends on the material) | |

F-Theta Field Lens | Working area 300x300mm Focal Length 482mm | Positioning Accuracy | ±0.1 μm | |

Optional Lens | 70*70/110*110/200*200/300*300 | Power Consumption | ≤1000W | |

Power Requirements | AC220V/50Hz Or AC110V/60Hz(According to local electricity supply) | Fiber Power | Adjustable from 10-100% | |

Correction Software | CorFile2 | Operation System | Win7/Win8/Win10/Win11 | |

Rotary | D80 Rotary Attachment Set | Marking Format | AI、DXF、PLT、JPG、BMP、Bar Code 、QR Code、 etc | |

Warranty | 2 Year | Temperature/Humidity | 0-35°C;10-95%,Non-Condensing | |